Plumbing Supply

Plumbing systems are complex, expensive, and largely inaccessible when construction is complete. For those reasons, careful planning pays big dividends. A well designed plumbing system is capable of saving thousands of gallons of water every year.

Overview

Plumbers have made the switch from copper to PEX (Cross Linked Polyethylene) for most of the water supply lines in a house. Two of the most used variants are PEX-A and PEX-B. PEX-A is the preferred route to go.

PEX-A:

- More flexible – avoiding 90deg fittings. Which can reduce fitting cost, less chance of fitting failure, reduced labor cost, and improve water flow.

- More burst resistant to pressure and freezes than PEX-b.

- The fittings and tube allow more water flow through pipes. The fittings are full-port fittings, which are very close in diameter to the ID of their pipes.

- Material: $0.35/foot

PEX-B:

- The main advantage of PEX-b is cost. Cheaper tubes, fittings, and tools to install. Other than price, PEX-a holds all other advantages. So if you can afford the extra material cost, PEX-a is worth the upgrade.

- Material: $0.21/foot

Efficient Layouts

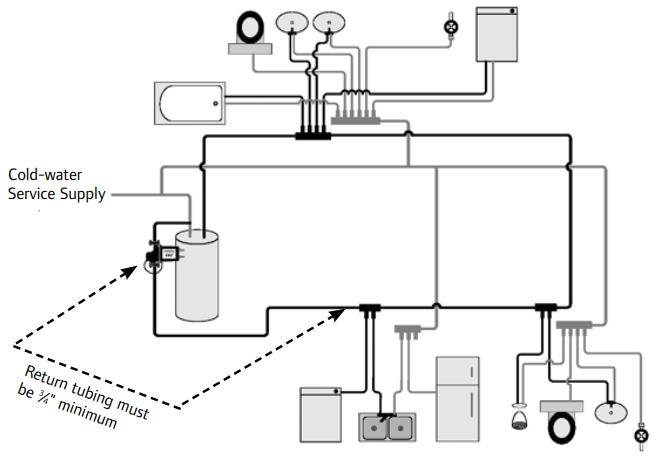

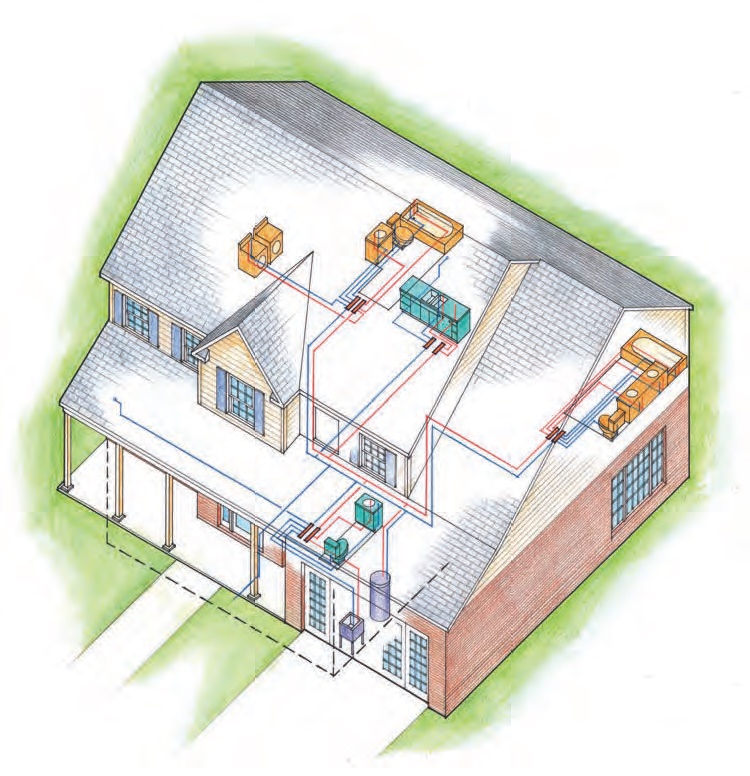

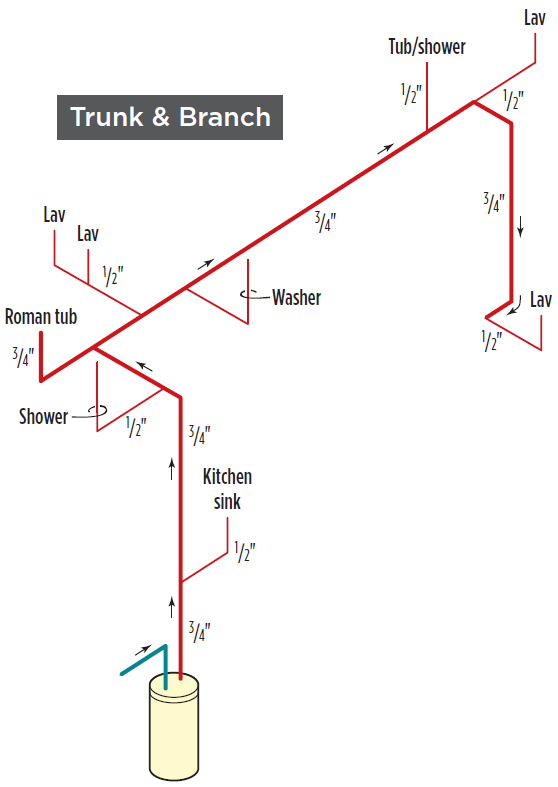

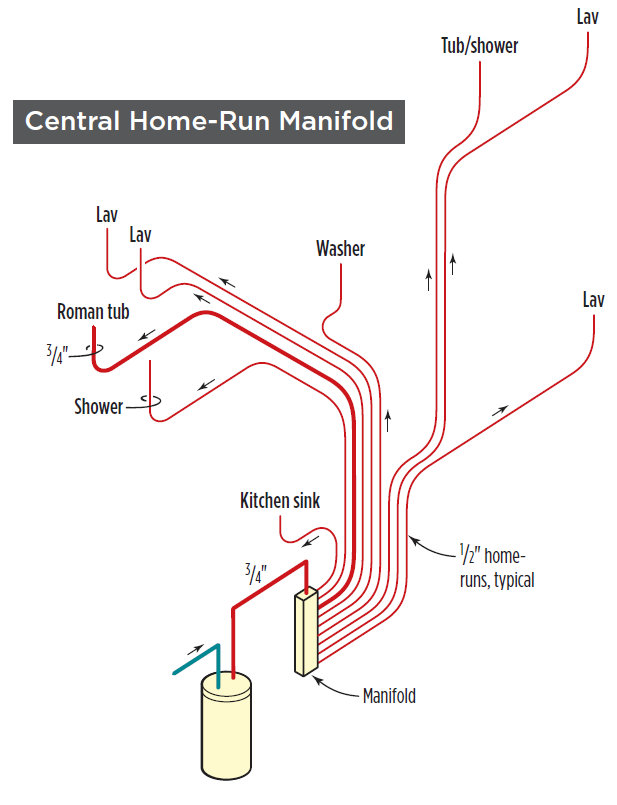

Heat losses increase with the diameter of the line, the distance the water must travel, and inversely with the speed at which the water moves. A large volume of slow-moving water sheds more heat as it travels to its destination than a smaller amount of water moving quickly. For that reason, zoned trunk-and-branch systems (or structured plumbing) save water and energy compared to conventional trunk-and-branch systems or home-run (manifold) systems. See images below.

Minimizing the amount of hot water that is wasted as homeowners wait for a sink faucet or shower to come up to temperature will save water (and in some cases, energy). If the source of hot water is at the other end of the house, this can quickly add up to thousands of gallons of water needlessly down the drain over the course of a year. If an on-demand water heater can be installed close to a kitchen or bathroom where most of a home’s hot water is used, it can partially alleviate this problem.

Match the plumbing layout to the floor plan. If a house is small enough, a home-run system with one main distribution manifold may be a good idea. In a larger home, it may be more challenging to group all rooms with plumbing around one chase. A Logic layout (or a "zoned trunk and branch system" or sub-manifold layout) with more than one cluster of fixtures may make more sense in this case. Or a structured plumbing approach pioneered by Gary Klein if you are wanting water recirculation.

In all cases, hot water lines should be insulated. Supply lines may run through chilly joist bays or walls on their way to a kitchen or bathroom. In winter, this energy isn’t really thrown away because it makes some contribution to heating the house, but in summer this heat loss is a complete waste that increases cooling loads. Insulating hot water lines is a relatively inexpensive way of reducing the problem and keeping heat where it belongs.

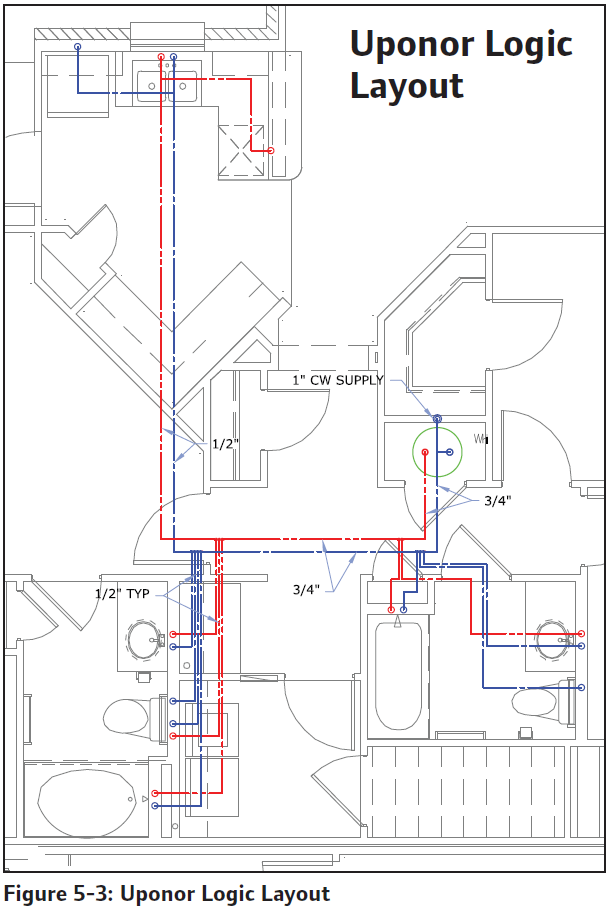

Logic

A Logic plumbing layout, named by Uponor could also be called a variation of a Zoned Trunk & Branch layout.

The Logic approach maximizes the flexibility of PEX pipe to reduce connections and potential leak points, while also incorporating multiport tees located near fixture groupings to limit the amount of pipe and number of connections needed and improve installation efficiencies.

This installation method uses considerably less pipe than a home-run layout, with only a few more connections, and it requires significantly fewer connections compared to a trunk-and-branch installation.

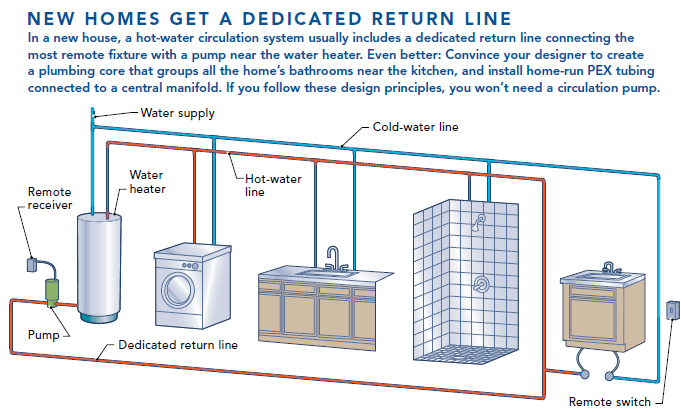

Once hot water arrives at a multiport tee, it is readily available to all fixtures connected to that tee. This layout also makes it easy to incorporate hot water recirculation. This is done by using a plumbing layout called Structured Plumbing along with a recirculation pump, like Uponor's D'MAND product.

Typical Trunk & Branch

In a trunk-and-branch system, the main supply lines, the "trunks," carry water to the general area where it will be used. Smaller-diameter tubing, the "branch" lines, get water to showerheads, faucets and other points of use. In residential construction, trunks are often ¾-in. dia. and branch lines ½ in.

A ¾-in. dia. supply line in a trunk-and-branch system holds a lot of water. When a hot-water tap is opened in a bathroom far from the water heater, all the water sitting in the ¾-in. pipe must flow through the system before any hot water reaches the user.

With a trunk-and-branch approach, all hot-water outlets in a bathroom can be served by a single return line and pump. If you get hot water close to the showerhead it will also be close to the sink.

Home-run, Manifold, or Parallel system

In a manifold system (also called a "home-run" or "Parallel" system), the hot water and cold water supply lines feed a manifold that distributes hot and cold water to each fixture in the house. Each fixture gets a dedicated valve and run of tubing from the manifold.

These systems have many advantages. In a home-run system, the tubing is usually only 3/8 in. or ½ in., so less water is wasted before hot water reaches the faucet. From an energy conservation standpoint they also have a drawback: they are harder to adapt to hot-water circulation systems. In a house with a home-run system, each hot-water line needs its own circulator. In either case, it pays to design the plumbing system to keep hot water supply lines as short as possible and to make sure they are well insulated. Green building guidelines from the National Association of Homebuilders recommend runs of no more than 30 ft. between the water heater and bathrooms and kitchen. Stacking bathrooms over one another and moving the hot water heater to a central location in the house are steps that can help.

Advantages:

- Water pressure remains stable to all fixtures when several are used at the same time.

- Simplified installation may mean lower costs.

- Home-run systems work well with open building systems, allowing less invasive, easier remodeling.

Hot water Recirculation

Hot water circulation saves water by getting hot water to the point of use with virtually no wait. Some hot water circulation systems save energy, while others increase energy use.

There are three types of hot water circulation systems: thermosyphon systems, time and temperature systems, and on-demand systems.

On-demand systems make the most sense in a green home because hot water is pumped to the point of use only when it is needed, minimizing standby losses. They are activated manually or by a wireless remote or motion detector. They are inexpensive to add when plumbing is being roughed in, and can be affordably retrofitted to an existing plumbing system. Installed as a retrofit, on-demand systems use existing cold water lines as the return with the help of a special valve.

Depending on the manufacturer of the equipment being used, a hot water circulation system pump is installed near the water heater or under the sink of the most distant bathroom. Systems that use the cold water supply as the return leg of the loop must include a normally closed check valve under the sink between the hot and cold water supply pipes. When the pump is activated, the check valve opens, allowing water from the hot supply pipes to cross over into the cold pipe.